Aeromodelling, the craft of designing, building, and flying model aircraft, is a fascinating hobby that blends art, science, and engineering. For enthusiasts, the allure lies in the meticulous process of constructing models that can soar through the skies with grace and precision. One of the most cherished materials in this craft is balsa wood, prized for its light weight and strength. Imported balsa wood kits, in particular, offer high-quality materials and intricate designs, making them a favorite among aeromodelling aficionados. Let’s delve into the world of aeromodelling and discover the beauty and precision of working with imported balsa wood kits.

The Significance of Balsa Wood in Aeromodelling

Balsa wood is a remarkable material that has been a staple in aeromodelling for decades. Native to South America, balsa wood is known for its unique combination of lightness and strength, which makes it ideal for constructing model aircraft. Its fine grain and easy workability allow for precise cutting and shaping, enabling modelers to create intricate and detailed designs.

Imported balsa wood kits are particularly sought after due to their superior quality. These kits often feature hand-selected wood that ensures consistency in weight and texture, resulting in more reliable and better-performing models. For aeromodellers, the use of high-quality balsa wood can significantly enhance the building experience and the performance of the finished aircraft.

Crafting with Precision: The Building Process

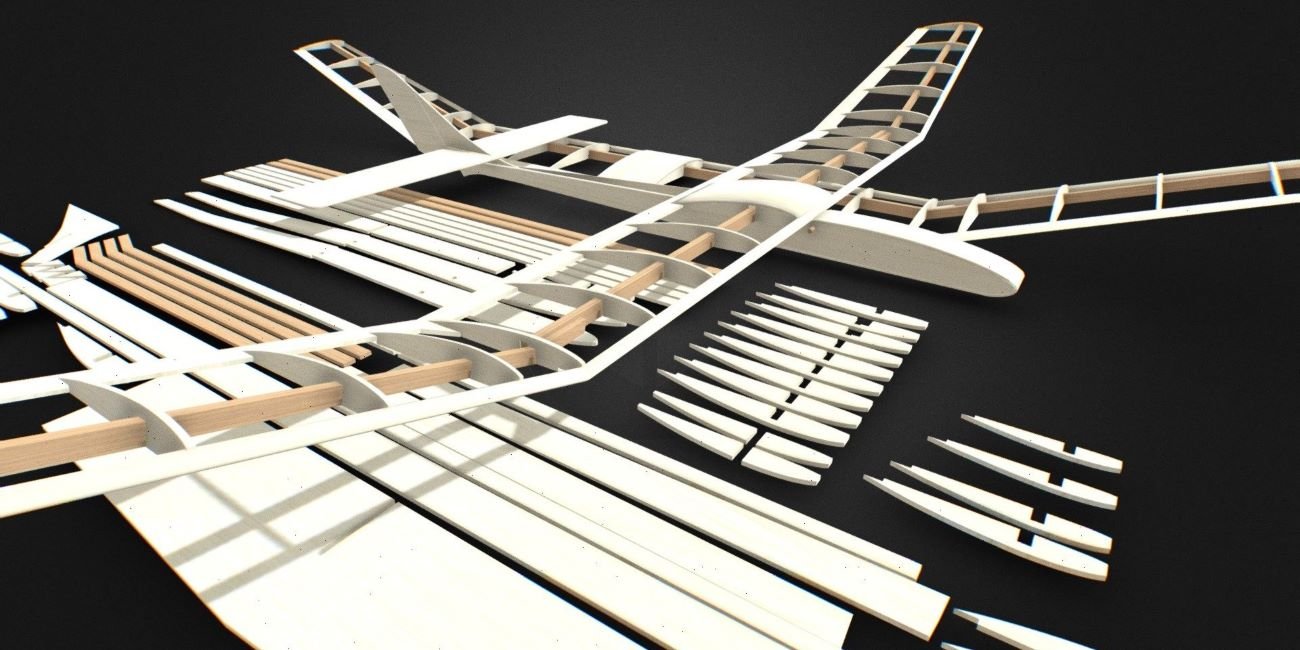

The process of building a model aircraft from an imported balsa wood kit is both an art and a science. It begins with selecting the right kit, which usually includes pre-cut pieces, detailed plans, and sometimes additional materials like covering film and hardware. The first step is to carefully examine the plans and familiarize oneself with the components.

Assembly typically starts with the construction of the fuselage, followed by the wings, tail, and other components. Each piece must be carefully glued and aligned to ensure structural integrity and optimal aerodynamic performance. Sanding and shaping are crucial stages where the modeler fine-tunes the contours of the aircraft, smoothing out any imperfections and ensuring that all parts fit together seamlessly.

The final assembly involves attaching control surfaces, installing any required electronics (such as servos for remote-controlled models), and applying a finish to the aircraft. This finishing process might include covering the model with a lightweight film or tissue paper and painting or detailing it to enhance its appearance and durability.

Understanding Aerodynamics through Modelling

One of the most rewarding aspects of aeromodelling is the hands-on understanding of aerodynamics it provides. By building and flying model aircraft, enthusiasts gain practical insights into how different design elements affect flight performance. This includes the shape of the wings, the positioning of the center of gravity, and the control surfaces’ configuration.

Experimentation is a key part of this learning process. Modelers can modify their designs, test different configurations, and observe the results. This iterative process mirrors real-world aircraft design and helps deepen the understanding of fundamental aerodynamic principles. For many, this blend of theoretical knowledge and practical application is what makes aeromodelling so engaging and fulfilling.

The Joy of Flight: Testing and Tweaking

The ultimate test of any aeromodelling project is, of course, its maiden flight. This moment is a culmination of hours of meticulous work and anticipation. Taking the model to the skies provides immediate feedback on the effectiveness of the design and construction techniques. It’s an exhilarating experience that combines the thrill of flight with the satisfaction of seeing one’s craftsmanship in action.

Flying sessions often involve a lot of tweaking and adjustments. Modelers might need to trim control surfaces, adjust the balance, or refine the propulsion system to achieve optimal performance. This hands-on problem-solving aspect is integral to the hobby, as it encourages continuous learning and improvement.

Community and Collaboration

Aeromodelling is not just a solitary pursuit; it is also a community-driven activity. Clubs, competitions, and online forums provide platforms for enthusiasts to share their projects, exchange tips, and collaborate on new ideas. These communities foster a sense of camaraderie and collective growth, as modelers support each other in honing their skills and tackling complex projects.

Competitions, in particular, offer an exciting opportunity to showcase one’s work and see how it stacks up against others. Events range from scale competitions, where models are judged on their accuracy and detail, to performance-based contests, where the focus is on flight capabilities and maneuverability. Participating in these events can be highly rewarding and inspiring, pushing modelers to continually strive for excellence.

Conclusion

Aeromodelling with imported balsa wood kits is a captivating hobby that combines creativity, technical skill, and a deep appreciation for the principles of flight. Whether you are a seasoned modeler or a newcomer to the craft, the process of designing, building, and flying these intricate models offers endless opportunities for learning and enjoyment.

Through precision craftsmanship and a keen understanding of aerodynamics, enthusiasts can create beautiful, functional aircraft that provide a sense of achievement and joy. Moreover, the supportive community and the thrill of flight ensure that aeromodelling remains a beloved pastime for generations to come. Embrace the art of aeromodelling, and let your creativity and passion for flight soar to new heights.

Leave a Reply